In This Article

What is ZIF Socket (Zero Insertion Force)?

The ZIF socket, or Zero Insertion Force socket, refers to the socket designed by Intel. It normally comes with a small lever that lets inserting or removing the processor chip of the computer easily.

Technically, it is an Integrated Circuit type of socket that allows installation and removal of chips without requiring any force or additional tools. Typically, the ZIF socket design is used by almost all sockets of the processors since Socket 2.

KEY TAKEAWAYS

- A ZIF socket refers to a kind of IC socket that does not require any force when inserting or removing a chip into or from it.

- A Zero Insertion Force socket allows inserting Pin Grid Array (PGA) chips by dropping the chip into the hole of the socket.

- There is a lever that is pulled down to hold the chip firmly in its place and pulling it up moves the pins into the contacts along with the assembly top plate.

- The ZIF socket is also used to connect the Central Processing Unit (CPU) to the motherboard of the computer.

- Most new motherboards come with a ZIF socket to lower the possibility of CPU damage during installation or to the other contacts during removal.

Understanding ZIF Socket (Zero Insertion Force)

A ZIF socket is a form of an Integrated Circuit (IC) socket, which also acts as the electrical connector of the Central Processing Unit (CPU) to the motherboard of the computer system.

Since no force is required during insertion or removal of the processor chip from the socket, these are called Zero Insertion Force sockets.

However, from the technical point of view, it is not truly a ‘Zero Insertion Force’ socket.

In fact, you will need very little force during installation or removal. This little force is required for the gravity to insert the chip into the socket.

This is minimized by the lever or the slider included in its design. The lever separates the spring-loaded contacts.

This further helps in placing the IC simply on top of the socket and inserting it inside with zero resistance offered by the parted pins between the opening and the contacts.

Sliding the slider or lever back into its initial position will close the contacts and grip the pins to hold the chip firmly in its place.

The ZIF socket is a significant innovation. It protects the chip from damage during installation or frequent removal from the socket.

Ideally, in most of the sockets, force is required to push an IC into the sprung contacts for a firm grip.

This causes friction, which acts as resistance while inserting the chip.

If there are hundreds of pins, as there are in a processor, it will need a much greater total insertion force, which enhances the chances of damaging the chip and even the motherboard.

Similar risks also loom for the smaller ICs with fewer pins when inserted into or removed from a regular socket.

This is because the force needed may bend the pins, which will eventually render them useless.

Need

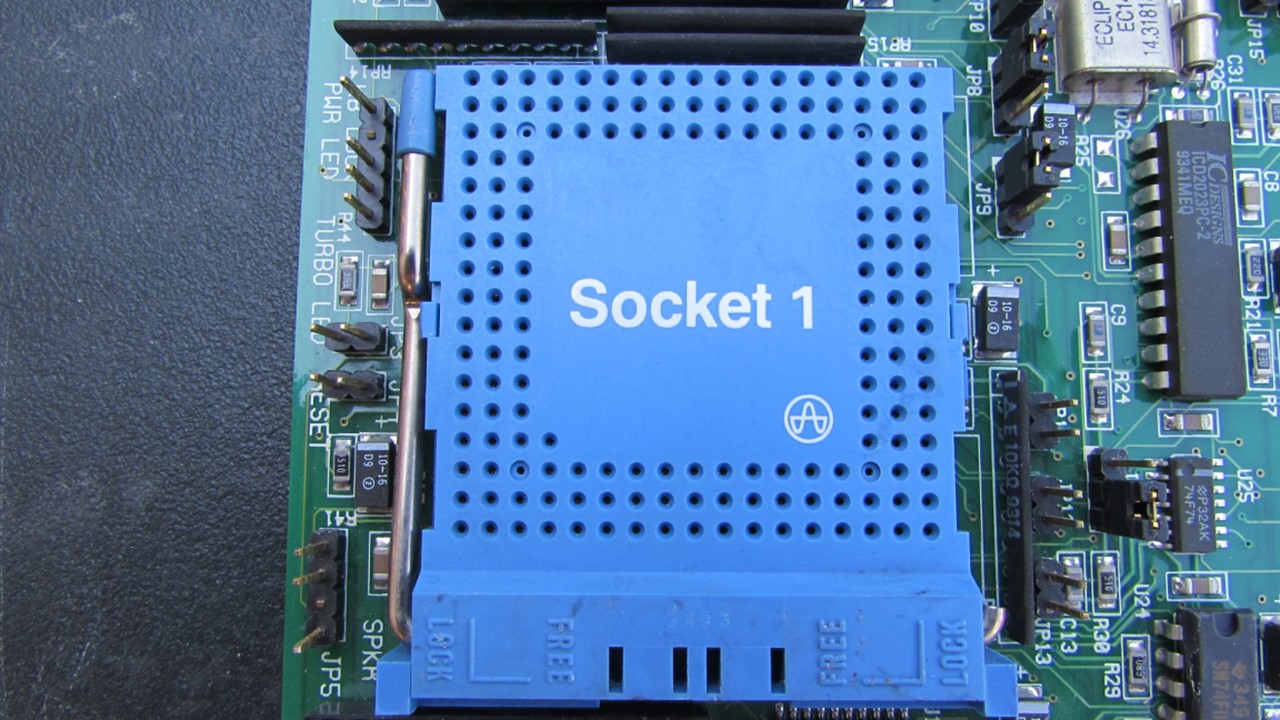

The need to design a ZIF socket was felt by the manufacturers when they did some math and realized that the Socket 1 specification did not make the process easy.

In fact, it typically took as much as 100 pounds of insertion force to install a chip into a regular 169-pin, screw Socket 1 motherboard.

With so much force, it is highly likely that the pins, the socket, or even the chip will get damaged during installation or removal.

So, the manufacturers focused on Low Insertion Force or LIF sockets. These sockets, however, needed much less force in comparison to the Socket 1 specification.

Still, it was quite high, measuring about 60 pounds of insertion force for the same 169-pin, screw Socket 1 motherboard. Therefore, the chances of damaging the chip were still very high.

Moreover, a force of 60 to 100 pounds exerted on the silicon motherboard could even crack it if there is no proper support given to it from the other side, which is less likely to happen most of the time.

Therefore, users typically resorted to removing the board completely so that they can provide support from the opposite side while inserting the chip into the other side.

This added to the inconvenience, risks, and time. Add to that, this needed additional and special tools as well.

So, low insertion force is very much relative and still risky.

Therefore, a better solution is still needed so that it will allow an average user to easily remove, replace, and insert a CPU, as and when required, without needing to use any additional tools.

Therefore, the manufacturers incorporated the special ZIF sockets in their newer Socket 1 motherboard designs.

Since then, almost every processor socket and motherboard has this special ZIF design incorporated into them.

In fact, since the period of 486 CPUs, removing them from the motherboards has not required any additional tools or force.

What is a ZIF Socket Used for?

The Zero Insertion Force sockets are primarily used to eliminate the risk of damaging the pins, chip, and motherboard during insertion and removal of chips.

It is also quite able to accommodate chips that come with a large number of pins and cannot be soldered onto the motherboard directly.

For example, in the case of desktop processors and motherboards, both are sold separately, and the CPU needs to be inserted into the motherboard by the user.

It allows installing and removing chips from the motherboard without any pulling, pushing, or using any tools.

There are also some other notable uses of the Zero Insertion Force sockets such as:

- The large ZIF sockets have been commonly used on computer motherboards since mid 1990s and onward.

- The smaller ZIF sockets are commonly used in programming equipment and for chip testing on microcontrollers, Electrically Erasable Programmable Read-only Memory (EEPROM), and others.

- These sockets can also be used for the Ball Grid Array or BGA chips, especially during development because these chips are quite unreliable and cannot grab all of the solder balls properly.

- The Zero Insertion Force wire-to-board connectors are usually used to connect wires to the Printed Circuit Boards or PCBs inside any electronic gadget. For example, such a connector is used to attach the motherboard and the LCD screen of the laptop computers.

- ZIF sockets are also used in probe connections for different ultrasound systems that need changing the probes frequently during different exams conducted throughout the day.

- ZIF sockets are extensively used in several industrial and automotive sectors for different testing and applications that specifically need repeated mating during the manufacturing of products.

- Several medical applications and equipment where frequent reconfigurations are needed to be made also use these special types of sockets and connectors.

- In a few specific cases of manufacturing products, the ZIF sockets are also used to permit field replacement of multi-pin, fragile arrays.

- The ZIF design is also frequently chosen for specific connectors used to mate flat and flexible cables to the motherboards of the computer system.

However, there is a significant downside to the ZIF sockets, which is their large footprint.

This is mainly due to the locking and unlocking mechanism in it, which is typically done with a lever.

This sometimes may limit its use in specific applications such as prototyping and testing that needs frequent removal and replacement.

How Do ZIF Connectors Work?

The working process of the Zero Insertion Force connectors is very simple, and all it needs is a proper connection. It is done simply by sliding the tail of the ZIF connector gently into the slot.

The movable piece in the connector will automatically lock it in its place by either swinging down or pushing it in by itself. The process is made even simpler with the inclusion of a lever in the design.

It is the proper connection between the processor on the socket and the motherboard through the connector that makes things work.

Therefore, you will first need to insert the CPU chip properly and then attach the connector in the right place and in the right way.

To install the processor chip, the steps to follow are:

- Pulling the lever to set the sprung contacts apart

- Inserting the chip

- Moving the lever back to its original position.

Now, insert the connector pin inside the respective socket so that it slides easily until the white mark which indicates that it is connected properly. The ZIF connector is now ready to work.

However, it is necessary to make sure that the ZIF connector is compatible with the ZIF tail. For this, you will need to consider four specific features such as:

- Pins – The number of pins on the ZIF connector should match with the number of pins on the ZIF tail. If it is small, it will fit, and if it is too big, the seating may be confusing, and it will take up much more space on the PCB than is required.

- Pitch – The distance between the individual pins, or pitch, is also very important to consider. It can be any of the three measurements, 0.5 mm, 0.3 mm, or 1 mm, and should be the same as the ZIF tail.

- Connection side – This indicates the side of the contacts, which can be either on the top or bottom, but in some cases, contacts can be on both sides. The orientation should be correct and correspond to the active area, even if the connector needs to be folded.

- Metal – Finally, the metal used in the connector is also very important to consider. Gold and tin are the two most commonly used metals, where the former is more expensive than the latter but is more durable. It will not corrode and therefore will not cause any short circuits between the pins. It is for this particular reason that the tin connectors are usually not recommended for a pitch less than 1 mm.

Remember, a proper connector will not compromise the connection and will not cause any noise to the system during operation.

How Do You Release a ZIF Connector?

To release, or even to plug in, the ZIF connector, the first thing you should remember is that you should not, and need not, exert any force.

For disconnecting the connector, you can simply use your fingernail or a pry tool such as a spudger for flipping the small locking flap up. Then you simply have to pull it out.

However, you will need to make sure that you pull out the connector safely. For that, you will first need to make sure that you follow these steps:

- Pry up on the hinged flap but not the connector socket

- Check whether it has a clip that lifts up or a sliding tab

- Lift the clip or slide the tab in the opposite direction

- Now just remove the cable gently.

If the connector was aligned perfectly, it should slide out easily.

When you need to reinstall a new connector, follow the same initial three steps and then slide in the connector gently, once again, until the white line marked on the ribbon cable.

This typically indicates the boundary of the connection area.

Finally, close the locking clip or sliding tab to hold the connector in place. Remember, if it is a sliding tab, it will be angled slightly internally.

This design aspect allows it to apply an upward or downward force, as the case may be, on the connector as well as on the cable when you push it in and hold them in place.

If you feel that the connector is not going in easily or it has not reached the white line on the cable, it is probably not aligned properly.

In that case, you will have to remove it gently and try once again, repositioning it properly this time.

Advantages

- Allows easy insertion or removal of chips with little force and no tools

- Little or no friction or rubbing occurs among mating contacts resulting in reduced mating wear and tear and a higher mating cycle life

- Easy activation of the engagement handle allows easy access to places difficult to reach with tools or two hands

- Double-duty mating of signal contacts within the metal housing

- Better EMI containment protection eliminates or minimizes electrical interference

- ZIF connectors eliminate the need for any additional connector

- It offers a direct connection between the circuit and mating connector

- Direct connectivity reduces cost

Disadvantages

- Much more expensive in comparison to any other regular IC sockets

- Takes up a larger area of the board due to its larger footprint and its lever mechanism

- Need for clean contacts for least mating wipes without insulating films

- Bulkier design due to the large number of contacts

- Larger torsion force and lever are required for the number of contacts

- Not suitable for dual beam contacts since ZIF connectors usually use single beam contacts

Does Intel Use ZIF?

Yes, there are several Intel processors that use ZIF or Zero Insertion Force sockets.

However, there are also a lot of other Intel processors that use other sockets such as the Land Grid Array or LGA 1200, 1151, 1150, and others.

Conclusion

ZIF or Zero Insertion Force sockets allow easy insertion and removal of electronic chips and circuits eliminating the risk of damage to the pins or chips.

Most new motherboards now follow the ZIF design for their sockets. Though these are relatively expensive as compared to the regular sockets, they are quite useful.